Numerical Control Machine

The precision and error of parts processing are the terms for evaluating the geometric parameters of machining surface. The accuracy measurement adopts tolerance grade, the smaller the grade, the higher the precision, the larger the value, the greater the error. Machining, processing error is small, on the contrary, the actual parameters obtained by the processing method do not mean that it is accurate. From the function of parts, as long as the machining error of hardware mold parts is within the tolerance range required by the part drawing, the precision of parts processing can be represented.

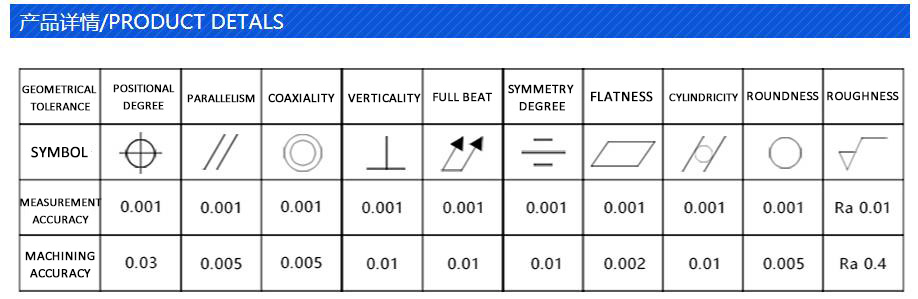

Position accuracy refers to the difference of the actual position precision between parts after parts are processed. There are eight methods to evaluate the position accuracy: parallelism, verticality, inclination, coaxiality, symmetry, position, circle runout and full run out. The position accuracy is controlled by the position tolerance, and the tolerance of each item can also be divided into 12 accuracy levels.

The relationship among the dimension precision, shape precision and position precision of die parts is analyzed. Generally, when designing machining precision of mechanical parts, shape error should be controlled in shape tolerance, and position error should be less than dimension tolerance. That is, the shape accuracy requirements of important surfaces of parts or parts should be higher than the position accuracy requirements, and the position accuracy requirements should be higher than the dimensional accuracy requirements

Products are widely used in medical and automotive industries

Lathe is a machine tool mainly used for turning the rotating workpiece. In the lathe can also be used to drill, reamer, reamer, tap, die and knurling tools for the corresponding processing.

Characteristics of lathe:

1. The low frequency torque is large and the output is stable.

2. High performance vector control.

3. It has fast torque dynamic response and high steady speed precision.

4. Slow down, stop fast.

5. Strong anti-interference ability.

Product Advantages:

One:Automatic production line, 24h production, 24h quality inspection

Two:All kinds of professional testing equipment and excellent quality inspection technicians

Three:ISO9001 international quality system certification and ISO13485 medical system certification

Four:Professional after-sales service, let you use more assured